Go behind the scenes at the Gibson Custom Shop in Nashville to meet the people who build your Gibson Custom guitars

If you’ve ever wondered what kind of care and attention goes into crafting a Gibson Custom guitar, this is the video series for you. The Gibson Gear Guide host, Dinesh Lekhraj, recently went behind the scenes at the Gibson Custom Shop to meet some of the incredible people who lovingly make your Gibson Custom guitar, sharing their experiences on the craftory floor and uncovering some pretty awesome guitars along the way, too.

How are Gibson Custom guitars different?

The hallmark of a Gibson Custom guitar is unmatched craftsmanship. Each heirloom-quality guitar is meticulously created by a team of individuals who bring—no kidding—over a millennium and a half of combined years of experience to their jobs.

The average tenure of expertise for these specialized artisans working inside the Gibson Custom Shop is eight years, and they pay close attention to every detail, from selecting the finest woods to precisely applying finishes that age like fine wine. Manufacturing all those classic Les Paul™, SG™, Flying V™, Explorer™, Firebird™, and ES™ guitars requires talent, dedication, and honed methods.

Each guitar undergoes a thorough setup process, including precise neck adjustments, fretwork, and intonation—and everything gets PLEK’d. This process—applied across all Gibson guitars—ensures that the guitar plays great right out of the box. Repair & Restoration Technician/Plek Operator, Kirk Eberhard, told us last year, that even this technology is human-guided, requiring knowledge and training to get the best results.

The components used on Gibson Custom instruments—pickups, tuners, and bridges—are of the highest quality. This enhances the sound and also creates extra durability and reliability. The innovative Gibson Pickup Shop team work alongside the Gibson Custom artisans to help you translate your musical ideas into electrifying realities. Where would we all be without the humbucker™ and the “Soapbar” and “Dogear” P-90s?

Image: No mention of Gibson Custom would be complete without showing you some instruments with the Murphy Lab treatment

With all this in mind, when the Gibson Cultural Influence team places a guitar into the hands of a groundbreaking artist, or in a film such as the Elvis movie or A Star Is Born, they can be confident that the instrument they are supplying represents something bigger than the sum of its parts.

Chief Marketing Officer Beth Heidt relates: “When our guitars are called upon or we are going to be placed in those sorts of stories, it’s just amazing to know that our guitars are a critical part of those incredible icons’ life stories, careers, and their music making. It’s always a deep honor to be a guitar whisperer to someone who is an incredible musician, to be able to help them be matched with the instrument that unlocks their muse. It just feels like a higher calling sometimes.”

Jenny Marsh, Director of Cultural Influence, adds, “There is no better feeling than opening up that case, smelling that nitrocellulose lacquer, and seeing people’s reactions to receiving the guitar of their dreams. There is a lot of pride that you feel when you see your products being represented in amazing films. It’s one of the best parts of my job.”

Part 1: Body blanks to binding

Now, on to even more good stuff: let’s take a behind-the-scenes tour of the Gibson Custom Shop to witness every step of your guitar’s creation and meet the skilled luthiers and craftspeople who meticulously handcraft each instrument.

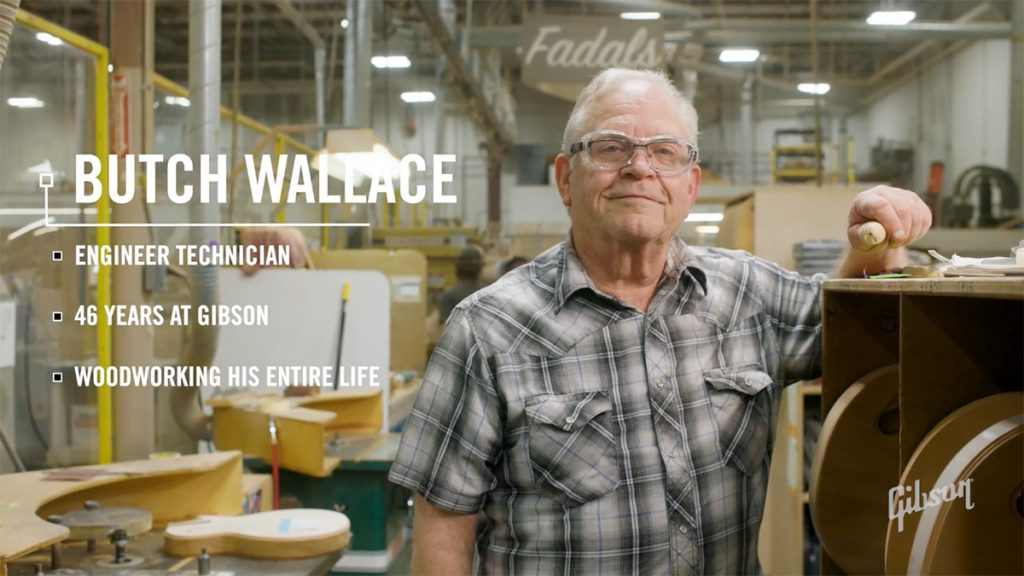

In part one of this video series, you’ll learn how a complete body is made, highlighting the team that takes it from body blanks to binding. Your guitar’s journey begins on the body line. Here, the tops and backs are sanded to the correct thickness and glued together. You’ll gain insights from Ian Smith, Biz, and Butch Wallace. Click on their photos to view that portion of the tour, or click on the provided links.

“A lot of people look at this place as just a job, but it gives you a good reason to wake up every day.” Ian Smith

“It’s like a family here.” Biz

Next, the body goes to the CNC machine for a first pass on the top carve, control routes, and the channel for binding. Binding is one of the most involved processes in making a Gibson guitar, whether at the Gibson Custom Shop or a regular Gibson model. Because it’s so laborious, it requires a high skill level and a lot of training.

Mat Koehler, VP of Products, says, “The most fascinating process at the Gibson Custom Shop, to me, is everything having to do with binding—not only the multiple top and back layers that need to be painstakingly wrapped on a Les Paul Custom but the century-old art of scraping the binding clean of paint, which requires a tremendous amount of skill and patience.”

Jeff Stempka, Brand Manager, Gibson & Gibson Custom, adds, “Walking into the Gibson Custom Shop is always a special experience. It never loses its magic. What I find most fascinating and impressive about Gibson Custom is their ability to essentially clone iconic instruments to a tee, and to do that across an entire run of instruments—and these are handcrafted instruments.

“The balance between art and science that the Gibson Custom Shop is able to achieve is so impressive. There is a lot of pre-planning that goes into replicating an instrument like Kirk Hammett’s Greeny or Jimmy Page’s EDS-1275—and a lot of it happens ‘off-stage’ in close collaboration with these iconic artists before the first prototype is even begun.

“I think that is also what fascinates and impresses me the most—the importance of ‘doing the homework’ and getting the details right up front. The passion for the craft is palpable at the Gibson Custom Shop—there’s an electricity in the air like something amazing is happening at every moment, and it really is.”

“It’s not just another job. It’s an adventure.” Butch Wallace

Whether you’re a seasoned musician looking for your next instrument or a collector seeking a piece of guitar history, explore the world of Gibson Custom guitars.

Visit your nearest authorized dealer or the Gibson website to learn more and find the guitar of your dreams—and be sure to pair your choice up with a fine Gibson or MESA/Boogie® amplifier, for the ultimate in tone.